Technical Specifications

| Model | GK2204(G4) |

| Machine drive form | Four-Wheel Drive |

| External expansion size | 5600×2780×3200mm |

| Wheelbase | 2830mm |

| Front and rear wheel track | 1950/2000mm |

| Gear position (forward/reverse) | 16+16 |

| Engine Manufacturer | Shangchai |

| Engine Model | SC7H240G4 |

| Engine rated power | 162KW |

| Power output standard speed | 760/850r/min |

Key Features

Zhenith 220HP Autonomous Tractors: Redefining Efficiency in Modern Farming

As agriculture advances, automation is becoming the key to maximizing efficiency and sustainability. Zhenith’s 220HP autonomous tractors lead this evolution, integrating intelligent technology to optimize farming operations with precision and reliability. Designed for large-scale agricultural tasks, these tractors enhance productivity while reducing labor demands, setting a new standard for the future of smart farming.

Overall View of the Tractor

This image features a bold blue tractor with a sturdy design, blending aesthetics and functionality. Its distinctive front-end design highlights its professional appeal in agricultural machinery.

Beyond its impressive appearance, this tractor is equipped with advanced autonomous driving technology. Featuring a high-precision satellite positioning system and intelligent sensors, it can accurately plan work routes without requiring constant manual steering. In autonomous mode, the tractor follows pre-set programs, operating seamlessly whether in straight-line plowing or curved-field tasks. This innovation significantly reduces labor dependency while improving farming efficiency and precision.

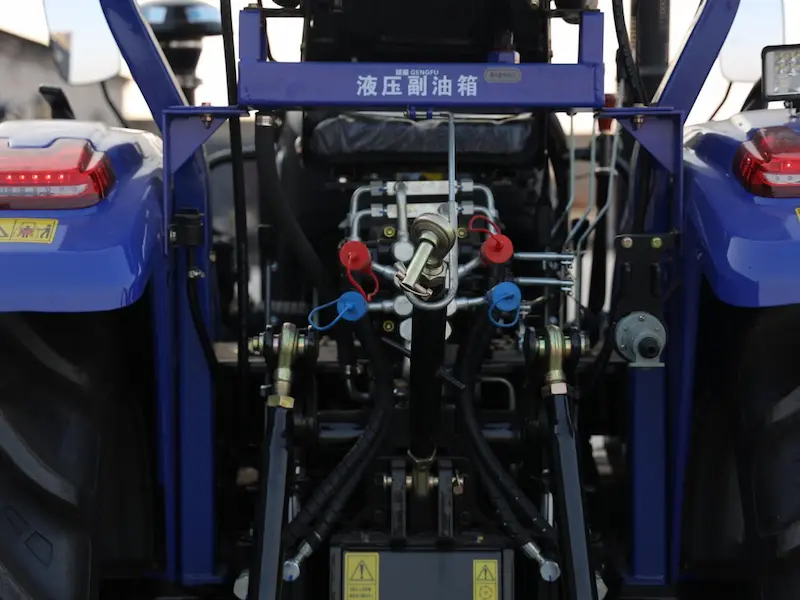

Hydraulic Auxiliary Tank Details

This image showcases the hydraulic auxiliary tank, where neatly arranged components and red-blue valves reflect precise engineering.

The hydraulic system plays a crucial role in ensuring the stability of the autonomous driving function. It provides consistent power for various automated operations, such as precise deep plowing and land leveling. The well-designed hydraulic auxiliary tank guarantees a steady supply of hydraulic fluid, allowing the autonomous system to function efficiently even during prolonged working hours. This ensures continuous, stable performance for high-efficiency agricultural production.

Interior View of the Cabin

2811437.webp)

The cabin view displays a well-arranged steering wheel, dashboard, and controls. The blue steering wheel and illuminated dashboard add a modern, high-tech feel.

The cabin serves as the control center for the autonomous driving system. The advanced display screen on the dashboard provides real-time updates on system status, work progress, and GPS positioning. Operators can easily switch between autonomous and manual driving modes with the push of a button. Additionally, the system includes an intelligent alert function, which provides warnings in case of abnormalities, ensuring operational safety. This smart and user-friendly design enhances both the convenience and efficiency of modern farming.

Chassis Structure of the Tractor

This image highlights the tractor’s chassis, with key components like the transmission and drive shaft securely mounted on a durable black frame.

The chassis structure provides a solid foundation for the tractor’s autonomous driving capabilities. Its durable design ensures stability during automated operations, allowing the tractor to adapt to various terrains. The advanced drive system works in tandem with the autonomous control unit, dynamically adjusting power output and speed based on real-time terrain feedback from the sensors. This ensures smooth and precise autonomous navigation across different working conditions, enhancing operational quality and efficiency.

Factory Worker Discussing Assembly Details with a Foreign Customer

A foreign customer attentively discusses the tractor’s assembly with a worker. The organized workspace reflects professionalism and precision in manufacturing.

The foreign customer is particularly interested in the autonomous driving system, frequently inquiring about the core components and quality control measures. The worker, leveraging extensive technical knowledge and hands-on experience, provides detailed explanations—covering everything from the precise installation of sensors to the standardized wiring connections. The customer expresses strong appreciation for the worker’s expertise and the meticulous assembly process. This in-depth exchange not only highlights the commitment to product quality but also showcases the tractor’s growing appeal in the international market, laying a solid foundation for further global expansion.